Based on reports from the Specialty Steel Industry Of North America, stainless steel doesn’t consist of just alloy but instead, it is a combination of a group of iron bases that contains about 10.5 percent of Chromium.

The combination of this Chromium and additional elements tends to boost the ability of stainless steel to be highly resistant to heat, resist corrosion, increase fabricating properties and also increase mechanical properties.

This article tells you how to cut stainless steel because most people find it difficult to do so when the time comes.

Interesting Read – Best Jigsaw For Cutting Curves

How To Cut Stainless Steel

Stainless steel can be used in a wide range of applications and this ranges from sculptures, bridges, cars. jewelry, sheet metal and so much more and here is something interesting about stainless steel, it is quite hard in nature and this makes it the perfect metal that can be used in coating other softer metals.

However, you would not be able to make use of stainless steel in any of these applications if you can not make it past the cutting process and that is why you have this article to show you how and also the best tools to make use of when cutting stainless steel.

We encourage you to pay close attention to whatever we say on how to cut stainless steel as well as the types of tools that can be used in cutting stainless steel;

Angle Grinder

The angle grinder is a simple handheld appliance that can be used for carrying out abrasive cutting. This is why it is also a good choice for cutting stainless steel plates and when it comes down to cutting stainless steel plates with this tool, you would also need the help of a blade and side grinder.

An angle grinder that has a five inches cut off wheel is the best tool that can be used for cutting stainless steel and for you to be able to make good use of this tool then it needs to be well balanced so you can have adequate control when cutting.

Positioning the disc of this cutting tool right at the center should be done as well and if it happens that the grinder isn’t stable then the wheel is likely to get broken or damaged.

After properly setting the cut-off wheel and grinder, you should make a line that you would cut using a marker then go-ahead to set the cutting tool on the material that needs to be reduced so it would properly align with the area that needs cutting.

You should lower the wheel of the cutting tool slowly to match the steel plate and make some efforts to push the disc along the line.

The disc should be allowed to cut through the steel panel so you can end up obtaining your perfect and desirable cut.

Dremel

The next tool that you can make easy use of in cutting stainless steel is Dremel and trust the Dremel tool to cut a wide range of materials thanks to its reliable cut off wheels. If you find a Dremel that is equipped with a high-quality resinoid cut-off wheel then such a tool can also be used in cutting high carbon steel materials.

Chop Saw

Chop saws are small handheld tools that are best used when it comes to cutting things pieces of stainless steel materials. Most people would prefer making use of the chop saw for cutting stainless steel material because of the additional power that it possesses via its air pressure but one thing that you need to truly consider when cutting with this tool is the type of blade that you cut with.

When working with the chop saw tool, it is also necessary that you make use of a face shield to protect your face from small pieces of steel materials that might be flying around.

Slowly mark the area where you would need to cut and also lower the blade slowly on to the material that requires cutting. You should make sure that cutting is done slowly without having to pause and you can also make use of a small polishing wheel with a grinder to get rid of few remaining steel materials and also for polishing every edge.

Circular Saw

The handmade circular saw is one that is perfectly suited for cutting a sizeable material of stainless steel and if you end up making use of the right type of blade then you are already sure or certain of cutting through thinner stainless steel materials.

The first thing that needs to be done is setting up a cutting blade that is designed using a stronger steel material and the board should be set using a plywood base so it can offer enough backing to mark the area that requires cutting. You should cut slowly so as to keep the blade in motion.

Jigsaw

If you want to make difficult cuts like curves then the Jigsaw small handheld tool is the perfect tool for it. The only problem you are bound to encounter while working with this tool is friction. Stainless steel material tends to heat up quite fast and this causes a spike in blade heat.

This spike is quite capable of submitting the metal to damage or causes it to turn soft. A way to deal with this issue is by making use of a tungsten carbide steel blade because it is heat resistant and the saw should be placed at a lower rate so as to cut down on friction heating.

When working with the Jigsaw, there isn’t any need for you cut aggressively so all that you need to do is allow the saw to do its job and you would end up getting the results that you desire.

Trendy Post – PVA Glue And Its Uses

Band Saw

This is the perfect tool for carrying out cuts on square rail stock and pipes and guess what, with this kind of tool, you are bound to carry out a cutting action even on surfaces that are horizontal.

This is achieved simply by lowering the blade down right through the metal and the blade of a band saw has a tooth similar to that of stainless steel and this is because it is made using tungsten carbide material. For obtaining smooth cuts then you should place the speed setting of this tool at a very low level.

Hacksaw

This is a fine-toothed saw designed with the primary aim of cutting metal and it is also a solid tool that can be used in cutting stainless steel cable. However, you would be needing a piece of wood and a vise when cutting stainless steel with this tool and you would also need to drill a hole from one end to the center.

Drill

In the case of a drill tool, it makes use of bits unless a hole cutter which has the shape of a cup while there are teeth all around the cup’s rim. The teeth of hole cutters are designed to be like every other blade and those with thicker teeth can be used in cutting wood while those with fine teeth can be used in cutting metal materials that are quite hard.

You should be able to make use of a special blade when it comes to cutting stainless steel material and you should set your drill at its lowest speed in order to obtain the desired results.

Tube Cutter

This handmade tool is designed around a stainless steel tube but it makes use of a rotating wheel for carrying out its cuts. Tube cutters are designed especially for cutting stainless steel materials and you can make use of its disc in marking out the area that you would need to cut.

After setting up the tube, the rotating knob should be used in placing the material at the end of the tool and you should continue rotating the knob until the tube stays well secured.

Hold the exposed end with one hand while holding the tube cutter with the other hand and rotating the tube cutter around the tube will prompt the cutter wheel to make cuts progressively. The disc cuts through the line right on the tube and the piece of tubing ends up falling off.

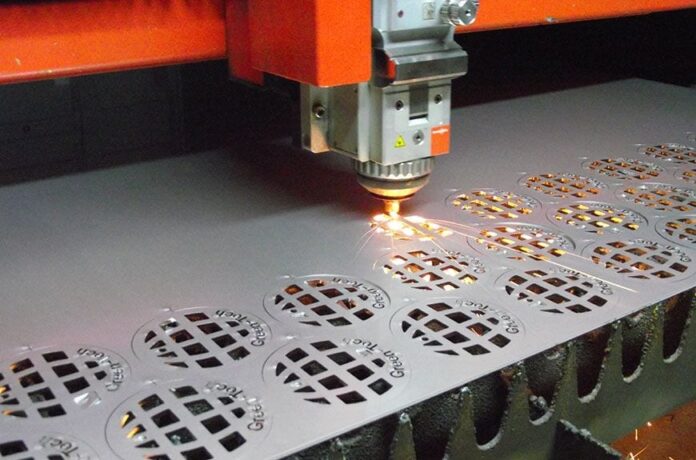

Plasma Cutter

The plasma cutter is simply the kind of tool that can be used when it comes to cutting large pieces of stainless steel material or panels. It cuts by using a concentrated beam of energy which ensures that even thick pipes are cut with minimal effort and all you need to do is placing the board on a steady surface while the negative cable should be clamped to your working area.

The cutting end should be placed about three inches away from the metal surface then you can begin running the cutter.

Running the cutter would should you how this tool burns through stainless steel panel with ease and you would also end up cutting along the straight line. In order to achieve desirable results, you must work using a steady hand so you can make straight cuts. You can also find sheet metal bending near me to ensure that the metal work is done perfectly.

Related Post – How To Cut Formica