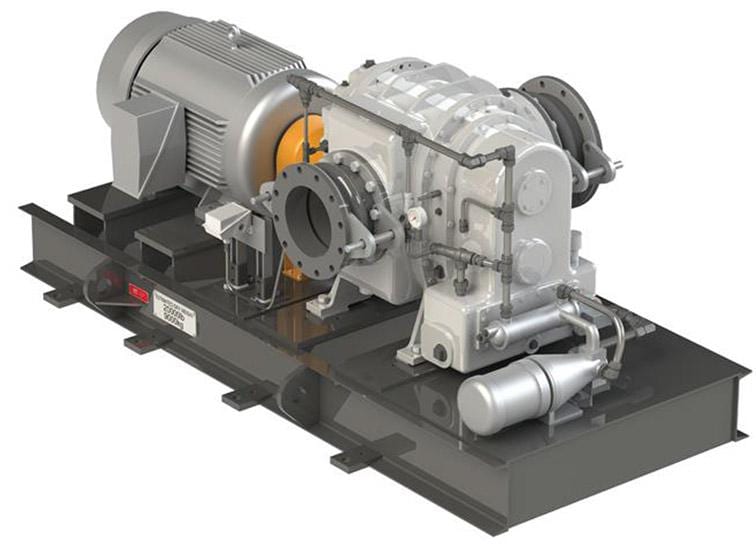

We don’t think about them often, but air blowers are essential to many devices that are both part of our industries and our home, and they have several possible purposes. They are most commonly used to increase the velocity of air or gas when it is passed through equipped impellers, which means that they can be used in exhausting systems, aspirating, cooling, ventilating, and in many other areas. So given how widespread their use is and how significant air blowers are, their maintenance is clearly important. It is always better to prevent than to fix a problem, and after all, the more efficient our devices are working, not only do we raise our productivity but also lower the cost of operations. So, if you require service, repairs, or installation of air blowers, just check out this website, but if you are more curious about the preventive maintenance of air blowers, here are the top four tips and tricks you can use.

1. Researching, installing, getting the best possible parts

While there are many maintenance things we should do regularly in order to prevent our air blowers from malfunctioning, there are also many small tricks and tips we should keep in mind on time. Now, some of them might require some understanding of how the machines we are dealing with work. For example, we could likely alter the place where the fan is placed to enhance how productive the air blow is. To accomplish this, you need to change its positioning, and you should do it in a way that diminishes the length of runs and straightening bends of the air blower. Ideally, we should also make it feasible for our air blower to have various types of airflow. With a multi-speed motor, it is absolutely possible to lessen the amount of energy we spend by over twenty percent. But even before we find ways to improve our machine by replacing some of its parts, we should probably do some research and think about what kind of air blower is ideal for the work we have in mind. Not all blowers are made the same, well, at least not equally adapted for every situation. So be sure to grasp what gadget is the perfect fit for you. That way, you can get the best possible blower out there, and once you do that, consider investing in some turning vanes, as they will help out with leveling the airflow in your device.

2. Rotation problems

When it comes to the maintenance of our air blowers, sometimes inefficiencies can be caused by quite obvious obstacles. One of the most noticeable issues that occur is having an air blower that has problems with rotating. Having rust in our blower’s impeller chamber is often the cause of this. Clearly, that means it’s time to clean, and in most cases, we can handle this issue by ourselves. But if that is too much for us, there is no reason to be shy and call some professionals. It is also possible that the motor winding in the blower system is broken, and when or if that happens, it is highly recommended not to try something out by yourself. Leave that to engineers that do that for a living. Another common issue is bad wiring connections inside the device. Again, it is probably not the best idea to try to fix this alone. Contacting experts is probably the smartest route we can take here.

3. Vibration issues

One of the things that could happen and prove problematic is a blower surpassing maximum vibrations. But don’t worry, it is pretty easy to notice this and try to correct the problem on time. So if you observe that your device is vibrating, be sure to turn it off and examine the bolts. Then investigate the foundation and the balance of the v-belt drive. Now, we mentioned some terminology here, and for those not familiar with its pieces, it would maybe be the best choice to leave the repairs to the experts. But if you are accustomed to this area of expertise, there are several things to look into that might be causing vibrating problems. There could be some problems with the bolts that cause them to fail, so be sure to double-check them. Lacking the v-belt pressure and disconnected sheaves in the v-belt could also cause some issues. Or something could simply be loose, either the mounting or the foundation.

4. Temperature difficulties

Overheating can be a serious matter, and that is why everyone should think about it in advance. There are several reasons that could cause blower temperatures to rise too much, and one of them is closely connected to how fast our blower is actually working. If it is working too slowly, that can cause severe conditions, and then it will be way too hard for the blower to work afterward. Working too fast can also cause problems, and that is why it is best for it to operate at speeds designated by the manufacturer. But, there is another potential problem since there could be too much filth in the air filter. That is why it is essential to change the air filters in our device regularly. Now, various devices might work differently, and therefore they might need cleaning at specific times, and it would be ideal to consult someone who is more knowledgeable about the particular device. If the impeller is worn out, that could also prove problematic, so be sure to have it checked from time to time, and inlet airflow could be restricted due to obstacles. Like with the impeller, it might be too much to expect from us to monitor them all by ourselves, but that is why there are professionals to help out.

The bottom line

As we have seen, the most important thing when it comes to the maintenance of the air blowers is thinking ahead and being diligent. Consider what work this device will actually be doing, acquire the appropriate equipment, adjust it in a correct way and clean it regularly. If everything is done in a suitable fashion, you should be able to reduce the overall costs and increase the efficiency of its work.